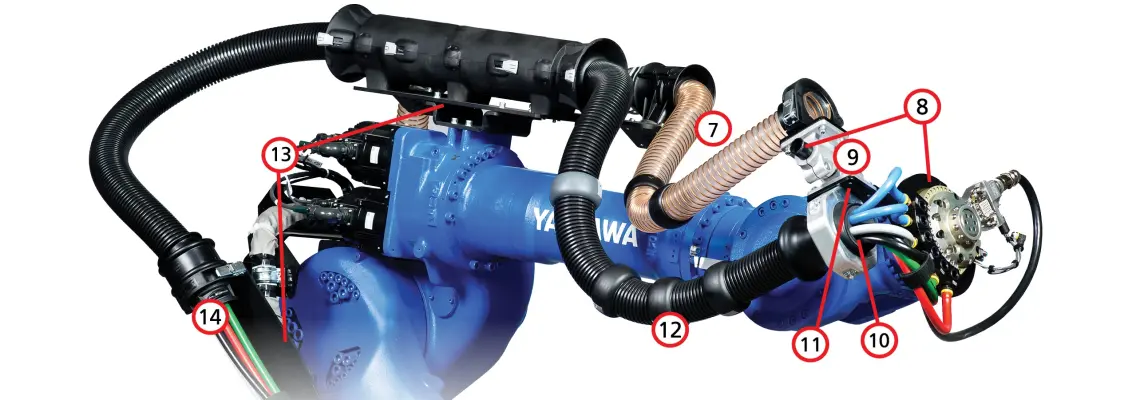

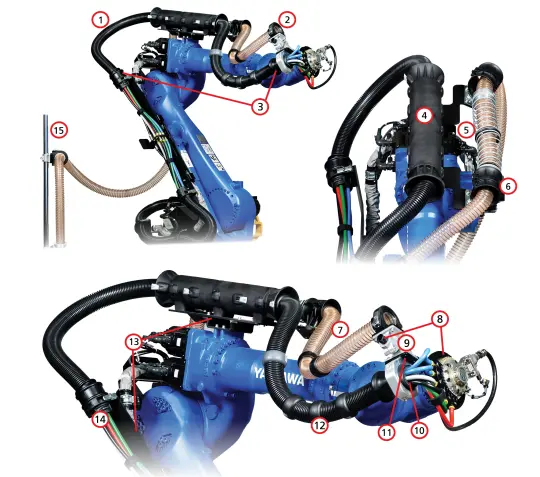

Robotic Dress Pack Component Basics

PROTECT – MANAGE – SECURE – GUIDE: Dress packages (a.k.a. dress outs, umbilicals, utility supply systems, etc.) provide an organized way of protecting the fill package from environmental hazards. This helps reduce time spent on preventative maintenance. Any industrial robotic application where an End Of Arm Tool (EOAT) needs various supply lines such as servo power, welding power, water supply, Ethernet communication, etc. would be in need of a dress pack.

Robotic dress packs are tasked with protecting, managing, securing and guiding cables and hoses over millions of work cycles. These high demands place an enormous amount of stress on every component within the system. Unfortunately, failures will occur. It’s a matter of when, not if a problem will arise. Over 85 percent of robotic downtime is attributed to fill package failures. In order to mitigate failures in the best way possible, it is important to select solutions from an application specific, as well as an overall system, point of view. In other words, each robot has a task to perform. Therefore, dress packs should be specifically designed around the complete work cycle of each task. Many companies have “ready to install” systems based on a robot model; some have online design tools. However, these should only be considered as a starting point because the solution suggested may fit the robot but may not fit the application. Think of it this way, we wear different clothes based on the task or event, like mowing the lawn or going to a birthday celebration. Correct? You didn’t change but the “application” did.

As you read on below, we will explore some of the main components that make up a dress pack and explain the role they play in the protective system for your specific fill package.

Dress Pack Components

1.

Corrugated Tubing / Flexible Conduit

2.

System Holder

3.

Articulating Joints

4.

Spring Return System - Enclosed

5.

Spring Return System - External

6.

Trumpet

7. Vacuum Hose

8.

Ring Clamp with Pipe

9.

Pipe Clamp

10.

Cable & Hose Strain Relief

11.

Adapter Plate

12.

Impact Protector

13.

Metal Support Bracket

14.

Strain Relief Retainer

15.

Precision Tubing

Click each part name to learn more about the role they play in the protective system for your specific fill package.

ARTICLE DOWNLOAD

Click here to view this article in our digital download centre.